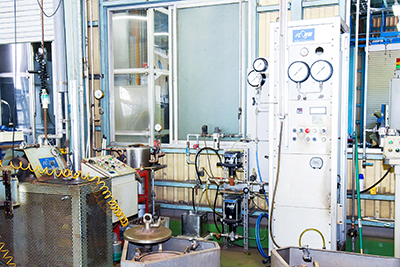

Work line with high and ensured efficiency was established by means of automation.

We perform inspection of cylinders that are used in medicals, foods, life rescue, industry, automobiles and many others.

We perform inspection of many cylinders with conditions that cannot be satisfied by our competitors,and thus have rich knowledge and experiences so that we are able to respond to our customers requests.

Outline of re-inspection

The re-inspections of general high pressure gas cylinders cover many kinds of cylinders, seamless cylinders for gases such as oxygen and nitrogen, general composite cylinders (FRP cylinders), compressed natural gas vehicle cylinders (CNGV cylinders), compressed hydrogen fuel cell vehicle cylinders (HFCV cylinders), and compressed hydrogen transportation vehicle cylinders.

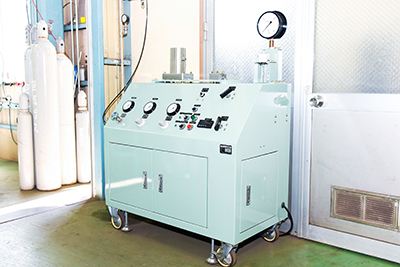

As for the facilities, we have full automatic shot blast, and inner surface air blasting machine. For pressure test, our system is equipped with water jacket method and non-water jacket method, switching the method according to the need. At present, up to 150MPa can be used. When accessory is attached, Helium gas can be used for up to 98MPa.

For coating, we design our own seamless cylinder automatic electrostatic coating system that is no other competitors, for coating with full color. Company name and gas name can be coated with high quality by introducing a printing unit.。

Re-inspection process

Removing valves

Pressuretest(Max.150MPa)

Shot blast machine (external appearance inspection)

Carved seal

Coating line

Automatic electrostatic powder coating

Baking

Valve installation

Printing machine

Finished items ready for shipment

Accessories reinspection(Max.30MPa)

Accessories reinspection(Max.98MPa)

Air blast

Air filling